Automotive Wire Harness is a wire integrated product that connects various electrical components of a car. It consists of many wires, injection molded connectors and several main components. Through precise weaving and braiding process, the cable has good electrical performance and durability. Let's introduce some basic knowledge of automotive wiring harness.

First, the material of the automobile wiring harness

The main materials of automotive wiring harnesses are copper wires, aluminum wires, copper-aluminum alloy wires, etc., which have the characteristics of good electrical conductivity, high tensile strength, and strong corrosion resistance. At the same time, the injection foam material is an important part of the automotive wiring harness. Its function is to protect the wires and connectors, and has the ability to isolate water vapor and cable flame retardancy, so as to ensure that the wiring harness can operate safely under continuous vibration and electrical conditions.

Second, the design of automotive wiring harness

The design process of the automotive wiring harness needs to be considered according to various factors such as different parts of the vehicle, the complexity of the electrical connection, the installation space and the installation style. Usually, the automotive wiring harness designer will determine the structure, size, shape, etc. of the wiring harness according to the vehicle electrical wiring diagram and wiring requirements, combined with the vehicle assembly process and waterproof, dustproof and other requirements. Simpler electrical systems can directly use standard wiring harnesses, while electrical systems with more complex and individual needs require multiple processes such as cutting, protection, and adjustment to meet the requirements of adaptability and reliability.

3. Processing of automobile wiring harness

During the processing of Wire Harness, various infrastructure and high-precision equipment are required to manufacture various types of connections. First of all, it is necessary to use automated equipment to complete the pretreatment processes such as processing, cutting, and threading of the wire harness, and carbonize and dry according to requirements. Then, follow-up processing steps such as installation of wiring boxes and wiring connectors, injection molding, and assembly are carried out. Finally, the wiring harness is installed or routed according to the needs of the vehicle.

4. Detection of automobile wiring harness

Automotive wiring harnesses are various electrical components used to drive vehicles, so each line must be carefully inspected. The quality inspection of automobile wiring harness includes multiple tests such as checking resistance, insulation test, cable stretching performance when bending and folding, cable force under mechanical vibration, etc., to ensure the reliability and safety of wiring harness operation.

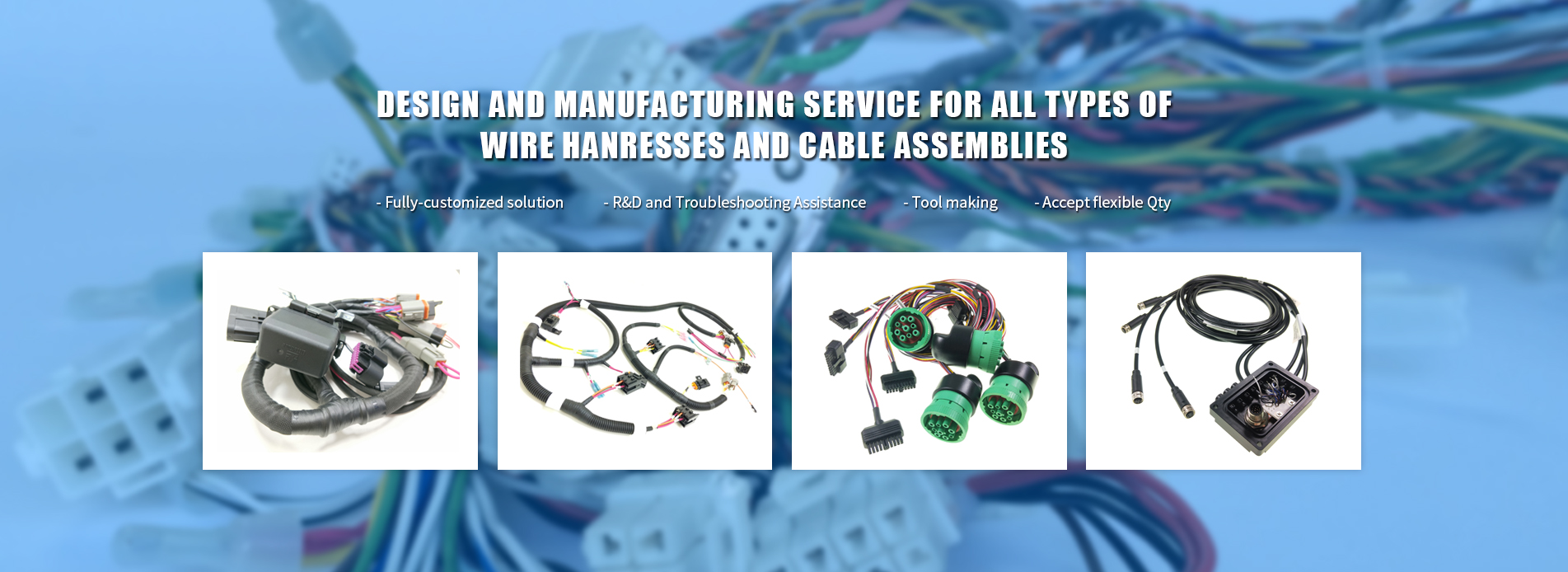

In short, as an integrated finished product that connects important electrical components, automotive wiring harnesses play a key role in the production and operation of vehicles. The design, processing and testing process of automotive wiring harnesses require the coordination and strict execution of multiple links to finally meet the performance and safety requirements of the vehicle. We support Custom Cable Assemblies, if you need, you can contact us.